The chitosan biopolymer is a polysaccharide derived from chitin deacetylation process, which presents extreme abundance in nature mainly to be found in the exoskeletons of insects and crustaceans such as crab shells and shrimp shells. The deacetylation is a key step in the chitosan production process, and consists in the transformation of the acetamide group (NHCOH3) amine (NH2) by reaction with a strongly alkaline character basis. This amine group, highly active, provides solubility in acidic media chitosan, differentiating it as soon as chitin.

During this process it is possible to vary the degree of deacetylation (DD) which follow previously established standards depending on the area to be applied. Degrees those which conform to a range between 70% to 95%. The main factors that affect deacetylation of chitosan and characteristics are temperature, reaction time, concentration of the alkaline solution, the particle size and the presence of heavy metals. The objective of this study was to evaluate efficiency of deacetylation process monitoring solubility, degree of deacetylation and yield as a function of temperature and reaction time. Characterization was carried out by Infrared Spectroscopy Fourier Transform Spectroscopy (FTIR) and X-Ray Diffraction (XRD), to monitor the GD and the crystal profile of the chitosan produced and ICP OES monitoring the presence of heavy metals. Results show the process efficiency by obtaining GD about 80%, and confirmation of the lens profile relating to chitosan.

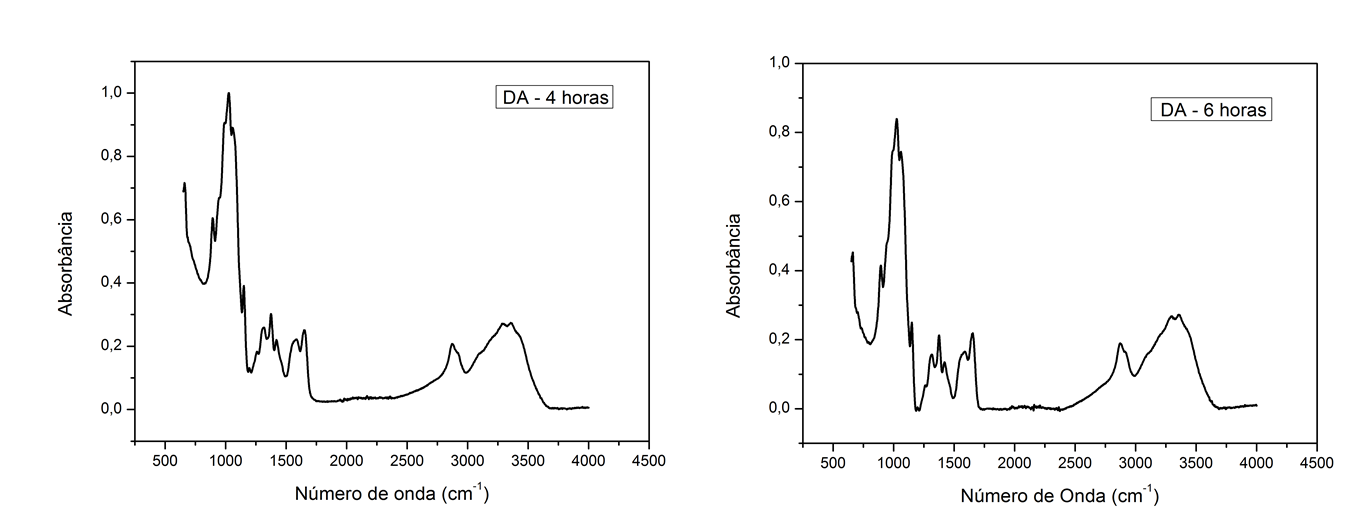

Infrared Spectroscopy Fourier Transform Spectroscopy (FTIR) - Chitosan with deacetylation of 4 hours and 6 hours

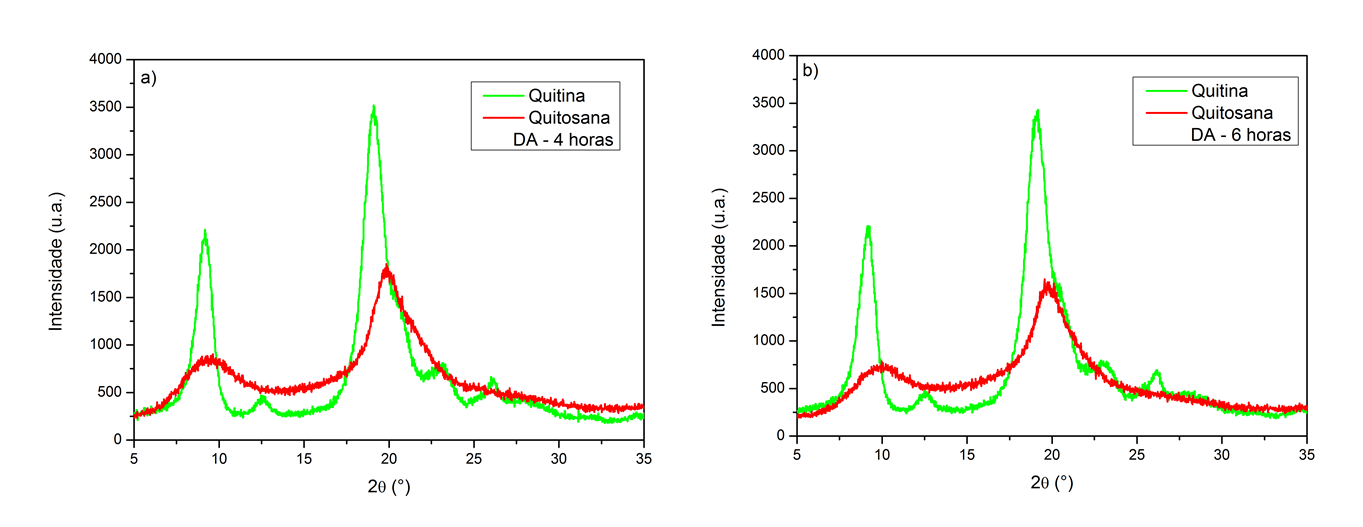

X-Ray Diffraction (XRD) - Chitosan with deacetylation of 4 hours and 6 hours and their respective chitin

CERTBIO; Ministério da Saúde

References:

[1] OLIVEIRA, Hugo Miguel Lisboa. (2012), “Produção de quitosano e desenvolvimento de novos materiais a partir de resíduos alimentares”.

[2] ROBERT, M. Enick, and J. Beckman Eric. (1992). "Chitin Chemistry, The.".

[3] KUMIRSKA, Jolanta et al. (2010), “Application of spectroscopic methods for structural analysis of chitin and chitosan”. Marine drugs, v. 8, n. 5, p. 1567-1636.