Introduction: Bioabsorbable polymers like poly(lactic acid) (PLA) are attractive biomaterials for regenerative medicine and tissue engineering applications due to their inherent property of in vivo resorption over time. However, the same useful property of hydrolytic degradation is a major concern from a manufacturer’s stand point. Studies have shown the influence of melt-processing parameters on the resorption behavior of these biomaterials[1]. For example, higher residual moisture causes rapid hydrolytic degradation during processing, and higher processing temperatures lead to de-polymerization, resulting in process induced monomers, which catalyze the degradation process. In addition, the extrusion rate can also affect the degradation profile. Thus, the goal of our study is to determine the optimum processing conditions for bioabsorbable polymers in order to achieve the desired properties of extruded fibers while preventing excess degradation during processing. We propose the use of molecular dynamics (MD) simulations along with the experimental approach to understand the thermal degradation of PLA under various processing conditions.

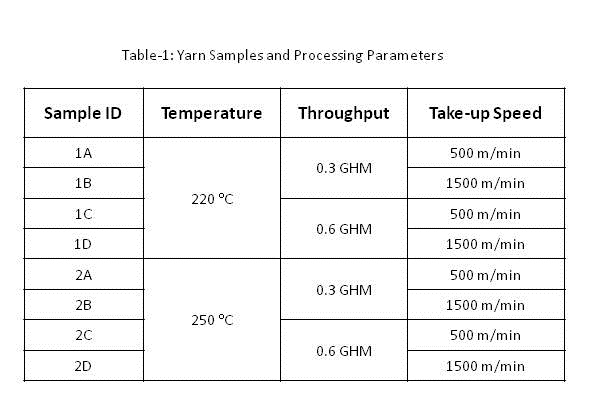

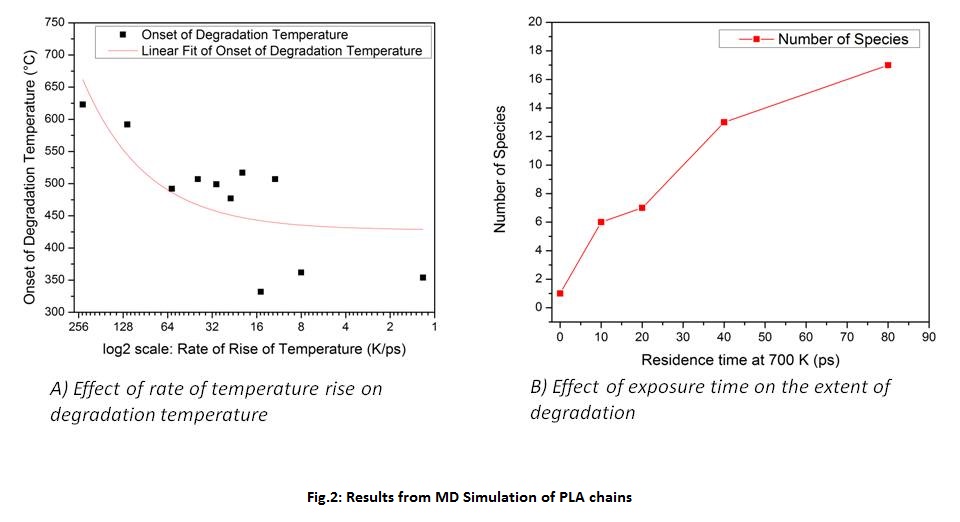

Materials and Methods: NatureWorks PLA polymer (6100 HP) was used for the experimental melt-spinning process to form PLA multifilament yarns. As indicated in Table-1, the effects of extrusion temperature, residence time in the extruder (correlated with the throughput), and the shear stress (as a function of take-up speed) were studied. The subsequent yarn samples were tested for mechanical and thermal properties.

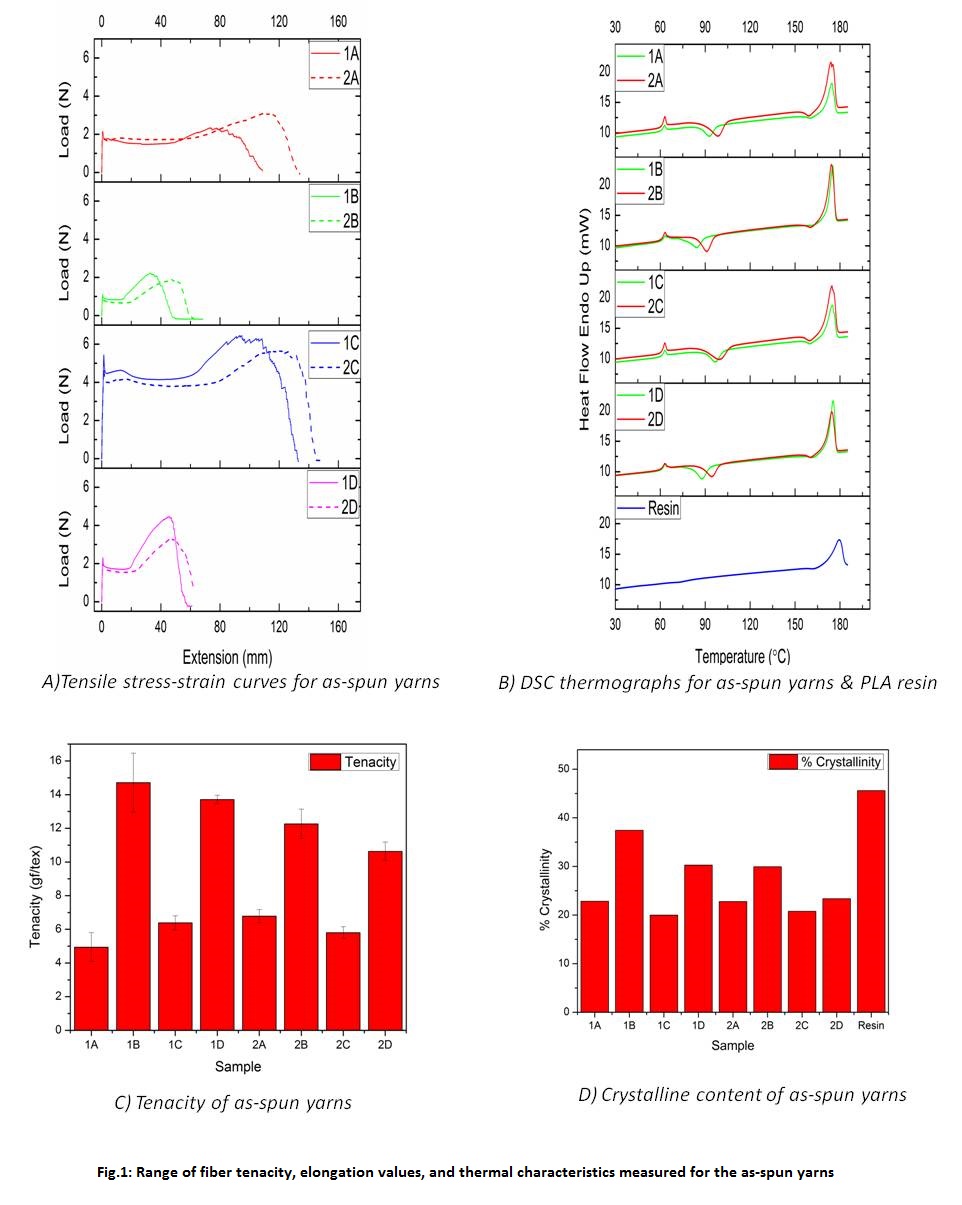

For MD simulations, the ReaxFF force field[2] was used with LAMMPS software[3]. First the PLA polymer chains were created using Materials Studio[4]. Twenty polymer chains, each with 20 repeat units, were packed in an amorphous cell (65 Å x 65 Å x 65 Å) with a density of 1.25 g/cc. The system was then equilibrated in LAMMPS at 300 K and 1 atm for 1 nanosecond (ns) using the NPT (constant pressure and temperature) ensemble and periodic boundary conditions. The equilibrated system was then used to study the degradation of the polymer chains, specifically as a function of the rate of raising the temperature, and the duration of the exposure to high temperatures.

Results and Discussions: Figure 1 contains the range of fiber tenacity, elongation values, and thermal characteristics measured for the as-spun yarns that were prepared with different processing parameters (Table-1). Due to different temperatures and take-up speeds, there was a difference in the orientation of the polymer chains and the crystalline content. The level of crystallinity also governs the tenacity, and a direct correlation was observed.

MD simulation results in Figure 2 indicate that at slower rates for raising the temperature, the degradation starts at relatively lower temperatures, whereas with prolonged exposure at higher temperatures, the extent of degradation increases.

Conclusions: PLA yarns with different mechanical properties can be formed by varying the processing parameters. MD simulations are an effective method to simulate the processing conditions and their effect on the degradation behavior of polymers. A better understanding of process-induced degradation will help to design resorbable biomaterials, such as scaffolds, with better control of their in vivo performance.

References:

[1] Oepen R. Clin Mater. 1992;10:21-28

[2] van Duin A. J. Phys. Chem. 2001;105;9396-9409

[3] S. Plimpton, J Comp Phys 1995; 117; 1-19

[4] http://accelrys.com/products/materials-studio/