Introduction: Titanium and titanium alloys are the metals used to produce metallic biomaterials. The alloy frequently used for orthopedic prostheses is the Ti-6Al-4V. However, there has been toxic effects due to the release of aluminum and vanadium ions. There are studies being directed on developing new alloys, specifically the type β-Ti alloys containing Nb, Mo, Zr, Sn or Ta, which are considered non-toxic, corrosion resistant and have mechanical properties suitable for biomaterials[1]. Nanotubular surface modification of metallic implants by the anodizing technique can improve the biocompatibility when compared to conventional materials[2]. The purpose of this study was to determine the elastic modulus of the Ti-20Nb and obtain the growth of the nanotubes over the binary alloy by anodization technique.

Materials and Methods: The precursor materials used were commercially pure titanium grade 2 (cp-Ti) with 99.7% purity and niobium (Nb) with 99.8% purity. For the fusion of elements it was used an arc-melting furnace with copper crucible water cooled, non-consumable tungsten electrode and an argon-controlled atmosphere. Titanium ingots with a weight percentage of 20 wt. (%) of Nb were obtained after melting process[3]. Disks with 9 mm of diameter and 2 mm of thickness were polished with a suspension of 0.05-mm colloidal SiO2. The samples were ultrasonically cleaned in acetone, isopropyl alcohol and deionized water, and dried at 40 °C for 24h. The microstructure of the chemically etched alloys was analyzed using optical microscope. The elastic modulus of the Ti-20Nb alloy were obtained by instrumented indentation by Oliver-Pharr method[4]. The nanotubes were obtained using anodic oxidation technique under potentiostatic mode in 0.5 M Na2SO4 + 0.1 wt.% HF electrolyte, using voltage of 20 V and anodizing time of 1.5 h, at room temperature. A platinum sheet was used as the counter-electrode. The morphology of the nanostructured surface was analyzed using scanning electron microscopy.

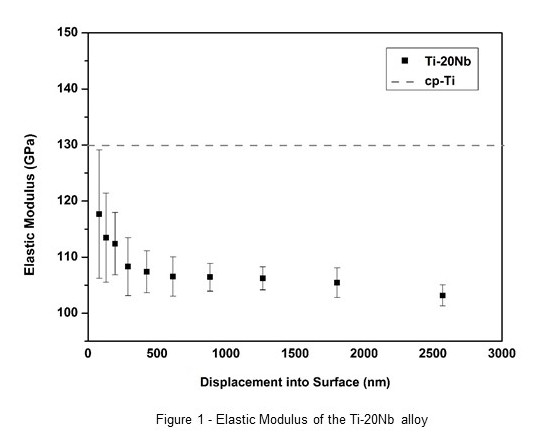

Results and Discussion: Optical microscope analysis of the Ti-20Nb alloy showed a structure composed of α’/α” phases and the metastable β phase. Figure 1 shows the elastic modulus value of the Ti-20Nb alloy is of (103 ± 2) GPa at greater depth (~ 2560 nm), which is smaller than the value of cp-Ti that is 130 GPa. This decrease in the elastic modulus is due to the presence of the β phase and can reduce the effect of stress shielding between implant and bone tissue.

Figure 2 shows the surface morphology of the anodized Ti-20Nb alloy, highly ordered titania nanotubes were produced. This morphology can improve osteoblasts adhesion ability and osseointegration compared to metal implants without surface treatment[2].

Conclusion: The adding niobium as β stabilizing element reduced significantly the elastic modulus, compared to cp-Ti. An ordered titania nanotube arrays successfully were obtained on the Ti-20Nb alloy, by anodization technique.

We would like to thank the Center of Electron Microscopy - UFPR and the Labnano - UFPR for the facilities, and the CAPES for the financial support.

References:

[1] M. Niinomi, “Mechanical Biocompatibilities of Titanium Alloys for Biomedical Applications”, J. Mech. Behav. Biomed. Mater.Vol. 1, Jan. 2008.

[2] M. Kulkarni et. al., “Titanium nanostructures for biomedical applications,” Nanotechnology. Vol. 26, Jan. 2015.

[3] L.M. Silva et al., “Influence of the Substitutional Solute on the Mechanical Properties of Ti-Nb Binary Alloys for Biomedical Use”, Materials Research. Vol. 15, Feb. 2012.

[4] W. C. Oliver and G.M. PHARR, “Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology”, Journal of Materials Research. Vol. 19, Sep. 2004.