Introduction: Synthetic polymers have been used for a long time in medical textile applications. Artificial vascular grafts for example, have been fabricated with non-degradable polymers such as polyester (PET) and degradable polymers such as polycaprolactone (PCL). In order to increase biocompatibility and patency, these synthetic polymeric grafts are usually coated with natural proteins, such as collagen. However, such post-fabrication coatings may not be stable on grafts and may need additional surface activation prior to coating. Therefore, the use of pure natural collagen as the yarn material itself has significant advantages for biomedical devices. In this study, the mechanical properties of pure collagen yarns were evaluated under different conditions of hydration in order to predict their suitability for fabricating into 3-dimentional woven grafts.

Materials and Methods: Pure collagen yarns were spun using the extrusion technique of linear electrochemical compaction[1]. Two ply yarns were then prepared by twisting two threads together, coating them with poly-lactic acid, and then dissolving the polymer in chloroform before testing. Yarn morphology and elemental analysis were measured by SEM coupled with energy dispersive X-ray spectroscopy (EDS). The tensile properties of the plied collagen yarns were measured in terms of maximum load, extension at maximum load, Young’s modulus and load at the yield point on an Instron mechanical tester with a crosshead speed of 10mm/min and 10mm gauge length. The control collagen yarns conditioned in an ambient environment were compared with hydrated collagen yarns (immersed in PBS for one hour) and dried collagen yarns (stored in a vacuum desiccator for 24 hours).

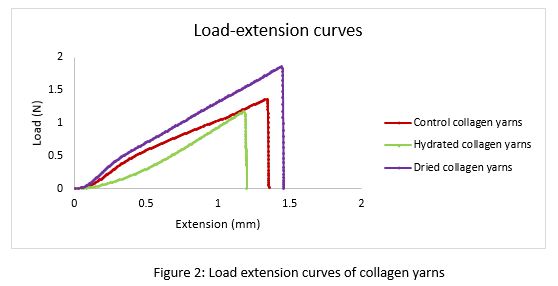

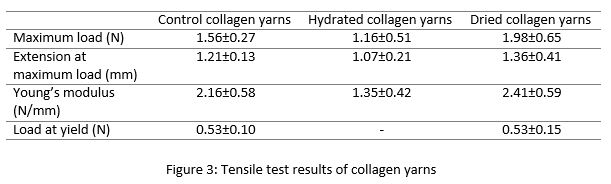

Results: Viewing the collagen yarns by SEM confirmed that they were composed of two ribbon-like filaments (Figure 1) and the EDS analysis showed that they contained 19.4 wt% nitrogen. The control and dried collagen yarns showed a normal load-extension curve with a yield point. However in contrast, the hydrated collagen yarns had no yield point (Figure 2). Both the maximum load and the Young’s modulus of the hydrated collagen yarns were significantly lower than the dried collagen yarns (Figure 3).

Discussion: Normally randomly oriented collagen does not have high mechanical strength. It is therefore often combined with other materials so as to be fabricated into implantable devices. However, the collagen yarns tested in this study present superior tensile strength that make it suitable for textile weaving, knitting or braiding processes and the fabrication into 3-dimensional medical devices. The absence of a yield point and the low tensile strength of hydrated collagen yarn may be due to the morphology changes within collagen associated with the disruption of hydrogen bonds between the peptide NH and CO groups by water molecules[2].

Conclusion and Future Works: From this study we have shown that the control of moisture during conventional textile processing of collagen yarns is important. Further evaluation of the degradation rate of collagen yarns and the change of tensile strength during degradation will be necessary prior to textile fabrication of biomedical grafts.

References:

[1] Younesi, M., Islam, A., Kishore, V., Anderson, J. M., & Akkus, O. (2014). Tenogenic Induction of Human MSCs by Anisotropically Aligned Collagen Biotextiles. Advanced Functional Materials, 24(36), 5762-5770.

[2] Huang, L. L., Sung, H. W., Tsai, C. C., & Huang, D. M. (1998). Biocompatibility study of a biological tissue fixed with a naturally occurring crosslinking reagent. Journal of Biomedical Materials Research, 42(4), 568-576.