Introduction: Superelastic Nitinol has been used as a rod material for dynamic spinal constructs to retain functional mobility of the spine and prevent adjacent segment degeneration[1]. It considered to have high corrosion resistance and is used for other implants such as stents, orthodontic wires, spine fixings. One recent report indicated that Nitinol was susceptible to corrosion[2] but the mechanism was not established.

The aim of this work was to investigate the fretting corrosion behavior of Nitinol spinal rods tested in-vitro in conjunction with titanium (Ti6Al4V) pedicle screws of different designs. Corrosion patterns observed after in-vitro tests were compared to patterns revealed on one Nitinol rod retrieved 12 months after implantation.

Methods: ASTM F1875 for the evaluation of fretting corrosion of modular implant interfaces was used as a guide in our tests. Electropolished (Ra 0.04±0.01 mm) Nitinol rods (55.8 wt.%Ni, austenite state, Æ5.5mm, l=76 mm) were locked in set screws (SS) or taper locked (TL) pedicle screws made of titanium alloy (Ti6Al4V, Fig. 1). In the SS pedicle screw the rod was locked by fixing the screw nut with a torque. The TL system rod is locked by press-fitting in the inner collet. A larger contact area between rod and screw TL system results in less mobility. Behavior of titanium (Ti6Al4V),CoCr rods and Nitinol rods attached to the same screw designs was studied. Nitinol rods were also tested using SS screws made from anodized titanium alloy.

Fretting corrosion tests used 3-point bending with a sinusoidal cyclic load with a maximal load of 650N (bending moment 12.4 Nm) and a minimal load of 100N at 1 Hz in 10% solution of calf serum in phosphate buffer saline up. Samples were tested for 3600 cycles, before c cyclic loading at 3 Hz for 2 million cycles. Resistance to fretting corrosion was evaluated by measuring values of fretting corrosion current and peak to peak (amplitude) current in potentiostat. An n of 3 was used. The surface of the rods after the in-vitro tests was analyzed using scanning electron microscopy (SEM) and energy dispersive analysis (EDAX). Statistical analysis was carried using a Mann Whitney U test.

The corrosion observed were compared to damage on the surface of Nitinol rod retrieved from spinal construct with SS screws with titanium screws 12 months after the implantation.

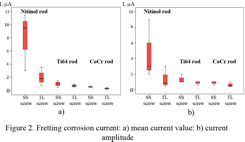

Results: Nitinol rods in SS titanium developed significantly (p=<0.05) higher fretting corrosion currents with mean current value being 9.5 mA and amplitude 3 mA. CoCr and titanium rods in these screws demonstrated lower fretting current values (Fig. 2). Nitinol rods locked in TL screws developed lower mean fretting currents compared with SS locking system however this was still significantly higher than with CoCr rods (p=<0.05) (Fig. 2). Testing Nitinol rods locked in anodized titanium SS screws significantly (p=<0.05) improved their corrosion performance with mean fretting current being 0.05 mA.

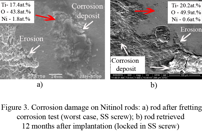

Corrosion damage on the surface of Nitinol rods where they were in contact with titanium screws was observed after the tests (Fig. 3a). Corroded regions with pits, combined with corrosion deposits of titanium dioxide (Fig.3a) were seen. The higher corrosion current was correlated with more extensive damage seen on rod surface after the test. Similar morphology and chemical composition of corrosion patterns were observed on the explanted Nitinol rod (Fig. 3b), which demonstrates the effectiveness of the in-vitro test to predict the in-vivo performance.

Discussion: Corrosion of Nitinol rods was found when tested in SS screws due to greater motion and although this reduced with the TL screws it was still greater than titanium or CoCr rods. There was an improvement of Nitinol corrosion resistance when tested in anodized titanium SS pedicle screws. The formation of corrosion products are not normally observed when Nitinol tested on its own or under fretting against itself [3]. Since corrosion damage observed on Nitinol rods may lead to premature fatigue failure and leaching of Ni ions, special pedicle screw designs and prevention of contact with o titanium alloy screws is important .

References:

[1] Yoshihara (2013) Spine J., 13(10), p.1350-8

[2] Reigrut (2013),STP1563,p.105-124

[3] Trepanier, SMST 2006, p.265-276