3D microfabrication for biomedical applications

-

1

University of Sheffield, Biomaterials Science and Tissue Engineering Group, Materials Science and Engineering Department, United Kingdom

Introduction: Tissue is the hierarchical organisation of cells and extracellular matrix (ECM). The ECM is a non-uniform and highly dynamic environment. Hence, there is a growing need for design and development of artificial scaffolds that mimic the natural ECM [1]. In this project we report the preparation of a microbristle based scaffold, which is built up of an array of high aspect ratio objects (microbristles). This array has been built up by two-photon polymerisation (2PP). 2PP uses non-linear absorption processes to construct three-dimensional structures with the resolutions up to. 100 nm [2]. This work mainly presents the fabrication of microbristles with the aim of 2PP as a fast, precise and versatile method. We aim to construct these microbristles as environments to selectively trap and subsequently release microobjects which would have great impact on cell culture and manufacturing of biomedical devices [3].

Materials and Methods: Photo-initiator was added to mixtures polyethylene glycol (700 g/mol) and carboxyethyl acrylate at the concentration of 4% wt. The doubled output of a pulsed microchip Nd:YAG laser was used (Alphalas, 532 nm, 0.5 ns pulsewidth, 46 kHz and 250 mW output), and the beam was focused on the sample to polymerise the photocurable resin. A shutter (Uniblitz) located between the laser output and the focusing lenses) and a high-resolution XYZ-stage (Aerotech), upon which the sample was placed, were controlled by computer-aided design (CAD) software. The photocurable resin was irradiated in an array of equidistant points. The uncured solution was properly washed with deionised water and subsequently with methanol, leaving the microbristle structure.

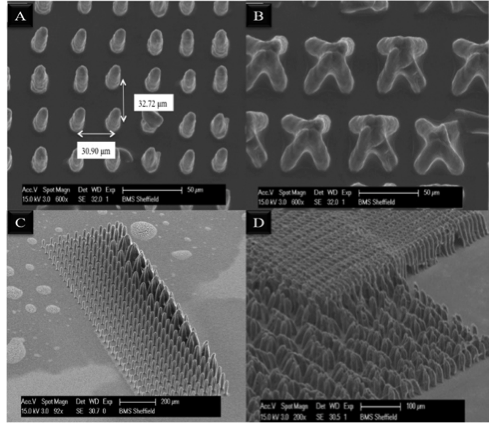

Results and Discussion: Microbristles made of 2PP are shown in Fig.1. During the washing process the bristles collapse upon each other due to the The elastocapillary effect. The microbristles can be rendered pH sensitive via incorporation of carboxyethyl acrylate. These pH responsive microbristle arrays are potentially interesting substrates for biosensors, and microfluidics based devices. 2PP is a versatile and powerful technique for direct write and shows clear advantages to more conventional approaches (e.g. soft lithography). To highlight the power of this direct write based approach intercalating patterns of microbristles were easily and quickly fabricated by 2PP using two different materials in a two-step process.

Figure.1: SEM image of Microbristles (A) height below the critical length for elastocapillary effect (B) height above critical length leads to elastocapillary effect (C, D) patterns produced with a range of different bristle lengths and spacings

Conclusion: In this abstract results on the use of 2PP for highly controllable manufacture of microbristle arrays have been presented. These microbristle arrays have been built from poly-ethylene glycol. Adding of carboxyethyl acrylate to the photocurable resin renders these microbristles pH responsive. Additionally, 2PP is a versatile direct write technique which lends itself to building complex multicomponent patterns.

References:

[1] Ma, P.X., Biomimetic materials for tissue engineering. Advanced drug delivery reviews, 2008. 60(2): p. 184-198.

[2] Wu, S., J. Serbin, and M. Gu, Two-photon polymerisation for three-dimensional micro-fabrication. Journal of Photochemistry and Photobiology A: Chemistry, 2006. 181(1): p. 1-11.

[3] Urdaneta, M. and E. Smela, Parasitic trap cancellation using multiple frequency dielectrophoresis, demonstrated by loading cells into cages. Lab on a Chip, 2008. 8(4): p. 550-556.

Keywords:

microstructure,

3D scaffold,

biomedical application,

polymer brush

Conference:

10th World Biomaterials Congress, Montréal, Canada, 17 May - 22 May, 2016.

Presentation Type:

Poster

Topic:

Three-dimensional fabrication

Citation:

Bahmaee

H,

Sherborne

C,

Claeyssens

F and

Laftsoglou

T

(2016). 3D microfabrication for biomedical applications.

Front. Bioeng. Biotechnol.

Conference Abstract:

10th World Biomaterials Congress.

doi: 10.3389/conf.FBIOE.2016.01.02076

Copyright:

The abstracts in this collection have not been subject to any Frontiers peer review or checks, and are not endorsed by Frontiers.

They are made available through the Frontiers publishing platform as a service to conference organizers and presenters.

The copyright in the individual abstracts is owned by the author of each abstract or his/her employer unless otherwise stated.

Each abstract, as well as the collection of abstracts, are published under a Creative Commons CC-BY 4.0 (attribution) licence (https://creativecommons.org/licenses/by/4.0/) and may thus be reproduced, translated, adapted and be the subject of derivative works provided the authors and Frontiers are attributed.

For Frontiers’ terms and conditions please see https://www.frontiersin.org/legal/terms-and-conditions.

Received:

27 Mar 2016;

Published Online:

30 Mar 2016.

*

Correspondence:

Dr. Hossein Bahmaee, University of Sheffield, Biomaterials Science and Tissue Engineering Group, Materials Science and Engineering Department, Sheffield, United Kingdom, Email1

Dr. Colin Sherborne, University of Sheffield, Biomaterials Science and Tissue Engineering Group, Materials Science and Engineering Department, Sheffield, United Kingdom, mta06cs@sheffield.ac.uk

Dr. Frederik Claeyssens, University of Sheffield, Biomaterials Science and Tissue Engineering Group, Materials Science and Engineering Department, Sheffield, United Kingdom, f.claeyssens@sheffield.ac.uk

Dr. Theodoros Laftsoglou, University of Sheffield, Biomaterials Science and Tissue Engineering Group, Materials Science and Engineering Department, Sheffield, United Kingdom, Email2