Introduction: In the process of testing new CAD/CAM-milled, patient-specific ceramic-on-ceramic (Lithium Disilicate, LS2) Temporomandibular Joint (TMJ) implants, stick-slip frictional noises similar to those found by others with all-ceramic artificial hip articulations[1] were noted. Surprisingly, when the plates or simulated joints were lubricated by water or saline to mimic the in vivo environment, the noise intensity INCREASED and shifted to higher-frequency components. This counter-intuitive finding was explainable as cavitation-induced vapor pocket implosion sounds from the shearing under pressure of effectively water-wetted ceramic over ceramic, as had earlier been noted with opening-closing motions of pyrolytic carbon heart valves[2]. This investigation sought to suppress such noises with a covalently bound monolayer coating of low-surface-energy, hydrophobic octadecylsilane (ODS).

Methods and Materials: Polished slices of heat-cured LS2 were provided by dental manufacturer IvoclarVivadent from ingots prepared for milling of aesthetic crowns of restored teeth. As supplied, they were water-wettable and further cleaned by Radio Frequency Glow Discharge Treatment (RFGDT) before friction measurement in ceramic-on ceramic couples in custom-constructed apparatus[3], dry and then water-wetted. The flat ceramic samples were then dried and again RFGDT before soaking in an ODS-benzene solution for conversion to hydrophobic surfaces by this C18, methyl-terminated hydrocarbon. Dry and water-wet friction measurements were repeated with the ODS-coated samples (3 cycles over a total elapsed time of 50 minutes). In both experiments, audible sound (squeaking) was monitored by ear.

Alternatively, in an implant application, 2 pairs of patient-specific curvilinear LS2 condylar surfaces and fossa segments were prepared by CAD/CAM-directed CEREC machining and articulated in a Proto-tech Oral Wear Simulator (impact-and-sliding) to simulate 6 months of wear. One pair was ODS-coated; the other was used as prepared. Open-source Audacity software was used to acquire noise signatures of sound intensity vs frequency for dry or wet, clean or ODS-coated condyle/fossa articulating couples.

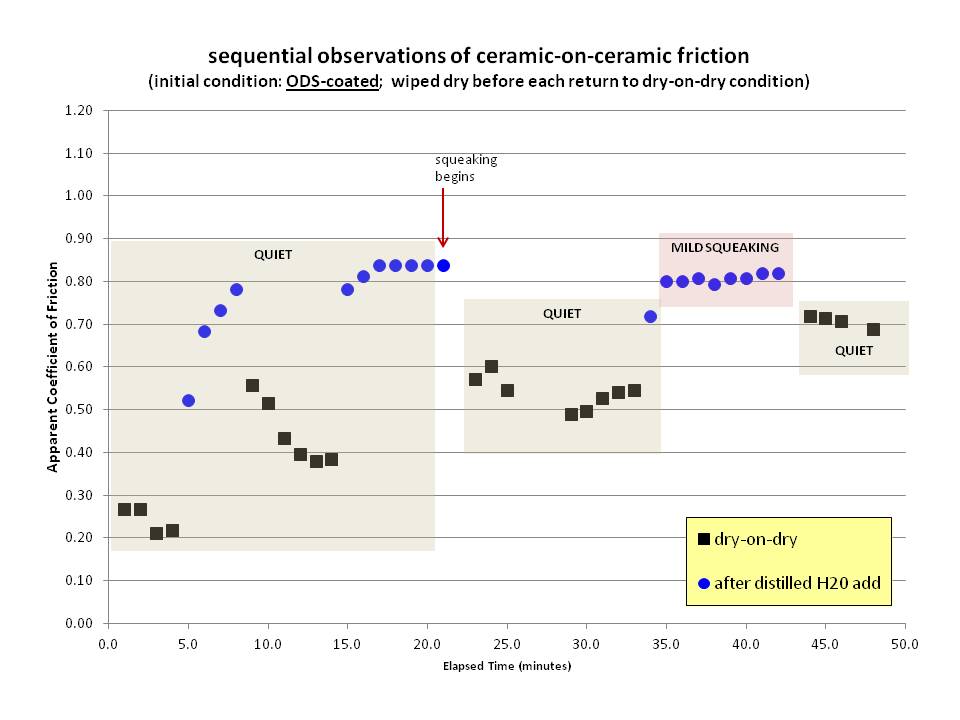

Results and Discussion: The dry-on-dry coefficient of friction (CoF) for the flat RFGDT ceramic-on-ceramic slices was reduced from 0.50 to 0.25 after coating the ceramic surfaces with covalently bound ODS. In both cases (RFGDT, ODS), the dry-on-dry conditions produced no squeaking sounds. When wet with distilled water, however, the flat RFGDT samples began to squeak immediately; the ODS-coated samples did not. After drying, both conditions returned to quiet operation. It was interesting to note that the apparent CoF of the flat ODS-coated samples increased when wet and, after 20 total minutes of wet and dry operation, began to squeak slightly (but only when wet). The dry-on-dry CoF of the ODS-coated samples gradually increased during the 50-minute experiment, which included 3 cycles of dry and wet conditions (Figure 1). In preliminary simulated wear experiments with condyle/fossa pairs, there was little difference in sound between the ODS-coated v. clean conditions. Both produced high-frequency squeaking after an initial period of relative silence. Surface analyses indicated that the ODS coating was removed during the 6-month simulation. Replicate experiments and analyses are in progress.

Conclusions: Prior literature for pyrolytic carbon heart valves demonstrated that collapse of separation-induced liquid cavitation bubbles was responsible for high-frequency sound accompanying jet impingement (cavitation) damage. Undesirable noise produced by wet ceramic-on-ceramic friction couples may also emanate from cavitation. A significant portion of this sound can be reduced by hydrophobic low-surface-energy coating of the ceramics, while also reducing CoF. Significantly improved longevity of the coating will be required to consider its application for clinical devices.

UB School of Dental Medicine - Dean's Vision Fund (CT)

References:

[1] Ki S-C, Kim B-H, Ryu J-H, Yoon D-H, Chung Y-Y (2011) Squeaking sound in total hip arthroplasty using ceramic-on-ceramic bearing surfaces. J Orthopaed Sci 16(1):21-25.

[2] Guo GX, Xu CC, Hwang NHC (1990) Laser assessment of leaflet closing motion in prosthetic heart valves. J Biomed Eng 12(6):477-481.

[3] Meyer AE, Baier RE, Chen H, Chowhan M (2006) Tissue-on-tissue testing of dry eye formulations for reduction of bioadhesion. J Adhesion 82(6):607-627.