Introduction: Laser micro-polishing is a process by which the surface finish of metals can be improved through a surface remelting phenomenon [1]. In this process laser beam is scanned over the workpiece surface and the formed molten pool tends to redistribute around the area adjacent to surface asperities. This process allows controlling the surface morphology in micro and nano scales, which is a crucial aspect for bacteria adhesion, since the surface features are comparable to bacteria in size [2]. In the meantime, the process can induce favourable changes in surface chemistry and wettability for avoiding bacterial adhesion [3].

Materials and Methods: In this work the suitability of laser micro-polishing to produce stainless steel surfaces with a good microbial removal capability was evaluated. Cold rolled 0.3 mm in thick AISI 304 (initial Sar=85.3±2.8 nm) laser micro-polishing was applied with a ns-pulsed fibre laser, working under different gas atmospheres (ambient atmosphere, N2 and Ar). The effects of different process parameters on surface roughness was investigated. A preliminary inspection allowed the definition of a polishing feasibility window and then polished surfaces were characterized in terms of average roughness (Sar) and waviness (Saw) through a focus variation microscope. On selected surfaces an escherichia coli assay was cultured and, after washing, adherent cells were counted with fluorescent techniques.

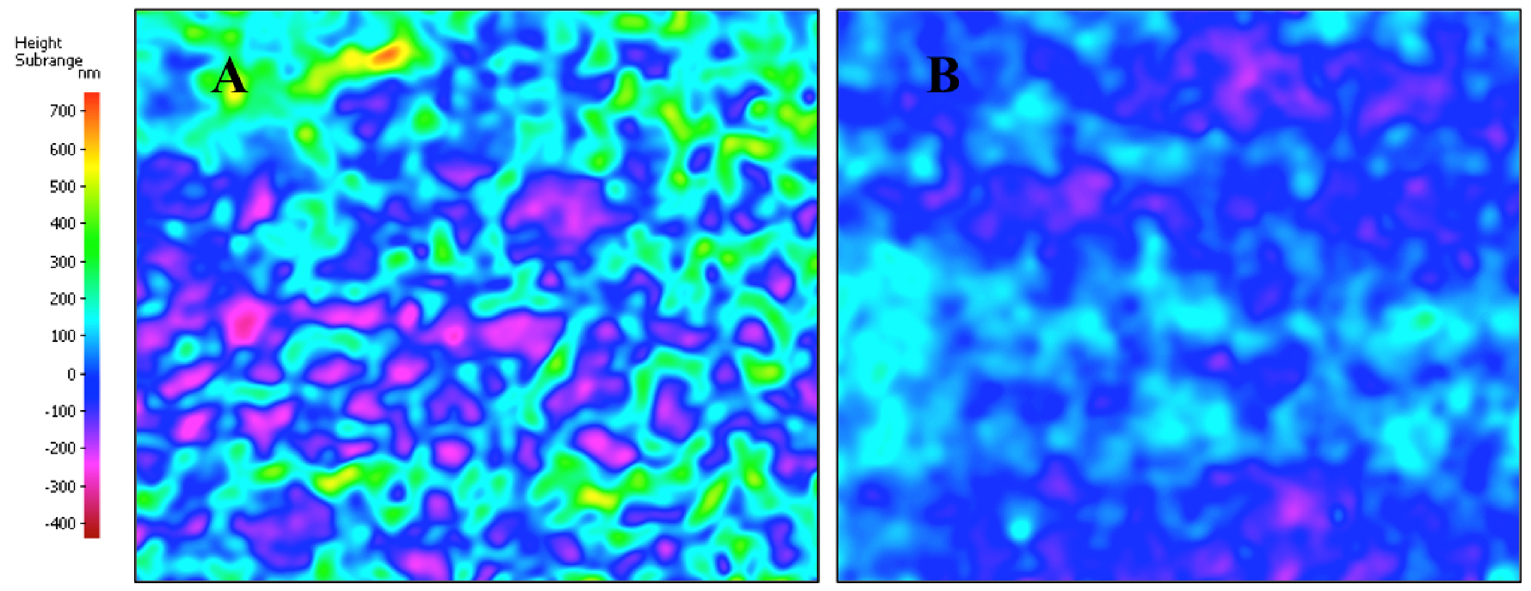

Results and discussion: An improvement on surface finish, with smoothing and grain boundaries removal, was possible working under N2 or Ar. A roughness reduction by about 60% (Sar =34.45 nm) was achieved. Five surfaces were selected: the most polished treated under N2 and under Ar, two antithetical ones and the as received samples for bacterial adhesion tests. It was observed that a higher number of particles was retained in grain boundaries on as received samples compared laser micro-polished surfaces. In this way bacteria, which usually attach to the immediate vicinity of the already attached bacteria, formed clusters that was more difficult to be removed. Moreover these agglomerates in grain boundaries were protected from unfavourable environmental factors and shear stress of washing solution.

Fig 1. Surface topography of a) bulk material, b) laser micro-polished surfaces (Image size 94.8 µm x 113.8 µm).

Conclusions: The surface smoothing, induced by laser micro-polishing treatment, generated surfaces easier to clean in terms of bacterial adhesion and other possible contaminants. The surface finish also improved the visible aspect, rendering the laser micro-polished surfaces suitable for consumer products, for example kitchen utensils or furniture that are in contact with food.

References:

[1] T. A. Mai, G. C. Lim, Micromelting and its effects on surface topography and properties in laser polishing of stainless steel, Journal of Laser Applications, 16 (4), 221, 200

[2] D. Campoccia, L. Montanaro, and C. R. Arciola, A review of the biomaterials technologies for infection-resistant surfaces, Biomaterials, 34 (34), 8533–54, 2013

[3] X. Zhang, L. Wang, and E. Levänen, Superhydrophobic surfaces for the reduction of bacterial adhesion, RSC Advances, 3 (30), 12003, 2013